Special & Custom Tanks

Special & Custom Tanks

Custom & Roto Mold Tanks

Explore the strength and versatility of custom roto mold tanks, perfect for commercial, agricultural, and industrial needs. Crafted seamlessly in one piece through rotational molding, these tanks offer durability and a range of texture and finish options to meet your exact specifications.

Looking for water storage solutions? We can help! Call us at 1-863-270-8118 or contact us to discuss your needs.

Rotational Molded Tanks

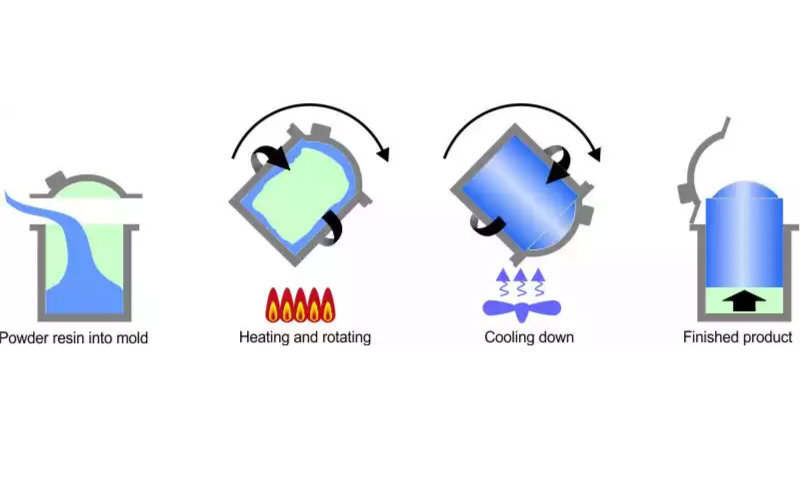

Experience the innovation of roto molding—a top-tier method for crafting custom tanks and products. This thermoplastic manufacturing technique excels in creating tanks for water, chemicals, diesel fuel, industrial use, agricultural water storage, and beyond. Lightweight yet durable, roto molded tanks boast exceptional rust and corrosion resistance, ensuring longevity in any environment. With roto molding, you have the flexibility to design tanks of any size and shape imaginable. Embrace limitless possibilities with roto mold tanks—your ultimate solution for versatile and reliable storage solutions.

Roto-Mold Tanks

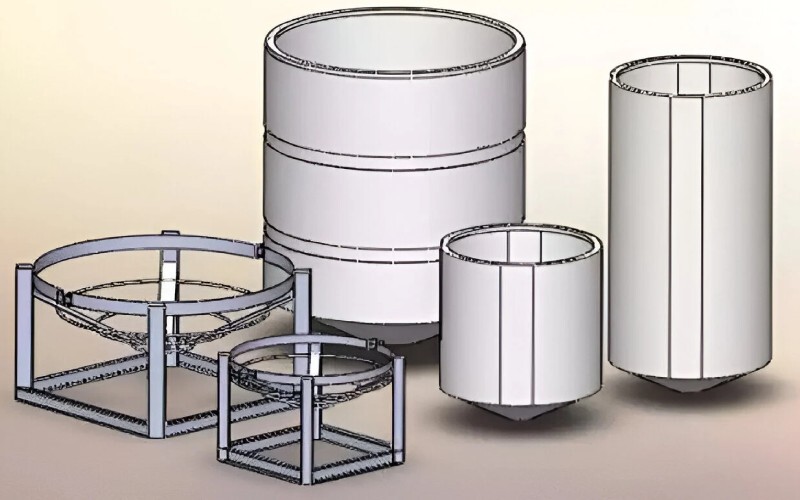

Explore our range of roto-mold tanks designed to meet diverse requirements:

- Vertical Tanks: Versatile and space-efficient storage solutions.

- VT with Containment: Ensuring safety and compliance with integrated containment features.

- Cone Tanks: Opt for open cone tanks for easy access and efficient fluid handling.

- Open Tanks: Discover the convenience of rectangular tanks for various storage needs.

Find the perfect roto-mold tank solution tailored to your specifications and ensure durability and reliability in every application.

Support Documents

Marine Tanks

- Bow Shaped Water Tanks

- Rectangular Water Tanks

- Rounded Corner Open End Compartments

- Square Corner Open Ended Compartments

- Wedged Water Tanks

- Battery Boxes

Marine Battery Boxes

- liLBattery Box GRP-31-DE

- Double Battery Box End X End GRP-31-DE

- Double Batter Box Side X Side GRP-31-DS

- Optima Battery Box GRP-34-SO

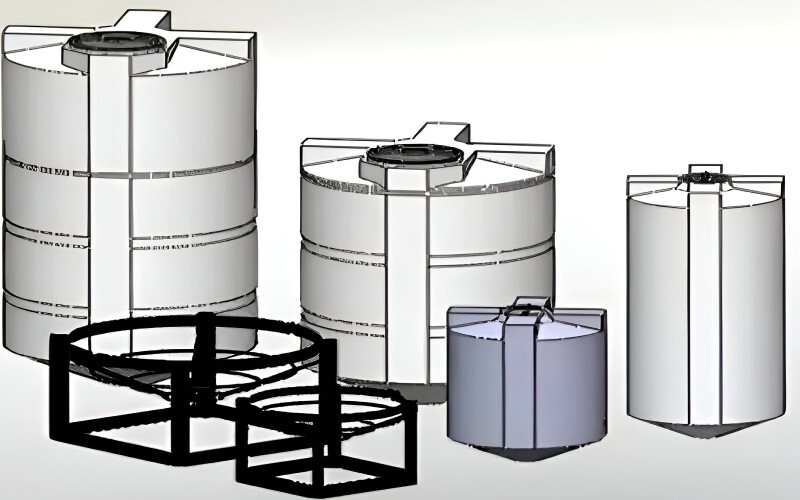

Agricultural Tanks

- Vertical Tanks

- VT with Containment

- Cone Tanks

- Open Cone Tanks

- Open Tanks

- Rectangular Tanks

Recreational Vehicle Tanks

- Bottom Dump Waste Tanks

- Bow Shaped Water Tanks

- End Dump Holding Tanks

- End Dump Holding Tanks with Rails

- L-Shaped End Dump Holding Tanks

- L-Shaped Side Dump Holding Tanks

- L-Shaped Water Tank

- Recessed End Dump Holi

- Recessed End Dump Holding Tanks with Rails

- Recessed Side Dump Holding Tanks

- Recessed Side Dump Holding Tanks with Rails

- Side Dump Holding Tanks

- Side Dump Holding Tanks with Rails

- Water Tanks

- Water Tanks with Rails

- Wedge Shaped Water Tank

- Fender Skirts

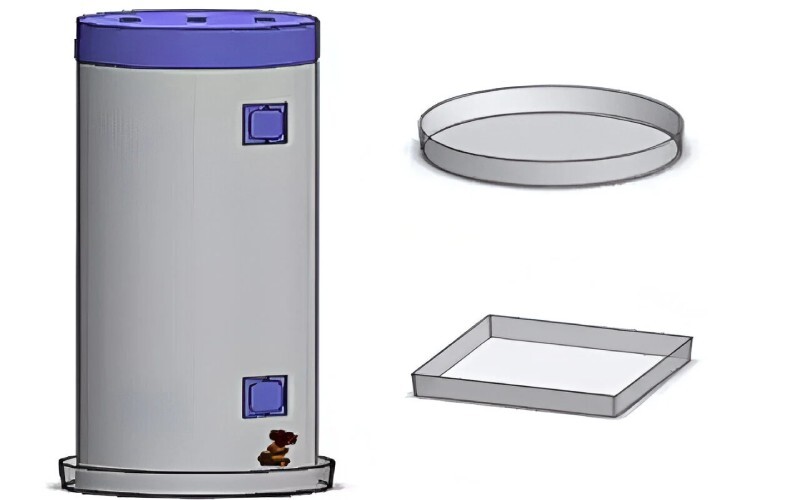

Water Heater Pans

- Vertical Tanks

- VT with Containment

- Cone Tanks- Open Cone Tanks

- Open Tanks- Rectangular Tanks

Tailored Rotomold Tanks: Precision from Concept to Completion

Experience a streamlined process with our custom roto molding services. We collaborate closely with you to understand your tank requirements and create a detailed prototype. Once approved, we craft a stainless steel mold to exact specifications and produce your tanks on state-of-the-art machines. Rigorous quality control ensures each tank meets our high standards, delivering durable, custom solutions for your projects. Contact us today to learn more about our roto molding expertise.

Versatile and Durable: Rotomold Tanks for Every Need

Rotomold tanks are the ideal choice for water storage and liquid containment, offering robust solutions across industries like agriculture, construction, and beyond. Designed for durability and leak-proof performance, they cater to specific applications such as rainwater collection, chemical processing, and emergency water supply. From farms to industrial sites, their versatility ensures reliable performance in diverse environments, making them essential for modern water management and storage needs.

Looking for water storage solutions? We can help! Call us at 1-863-270-8118 or contact us to discuss your needs.